UV Marble Sheet is a decorative material that mimics the luxurious appearance of natural marble through a special UV coating process. It has been increasingly favored in the field of interior design due to its remarkable aesthetics and practical features.

Linear Thermal Expansion Coefficient: ≤2.5×10⁻⁶/°C

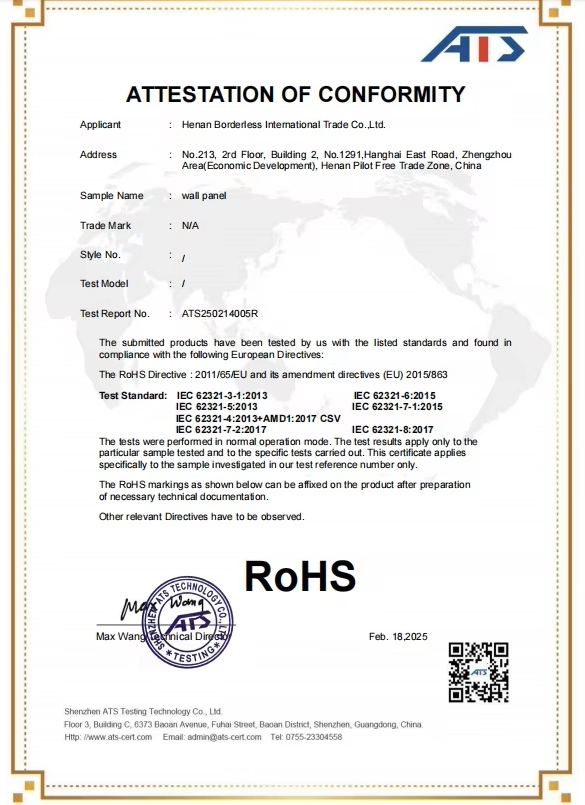

Radioactivity Certification: Class A (Highest grade for interior use)

Fire Rating: Class A2 (EN13501-1 Standard)

| Parameter | Description |

| Product Name | UV Marble Sheet |

| Application Scenarios | Interior wall cladding, ceilings, furniture surfaces, decorative panels for residential, commercial, and hospitality spaces (living rooms, bathrooms, kitchens, offices, hotels, etc.) |

| Raw Materials | PVC base material, UV coating layer, marble texture film, and stabilizers |

| Place of Origin | China |

| Surface Treatment | High-gloss UV coating for scratch resistance, waterproofing, and a glossy marble-like finish |

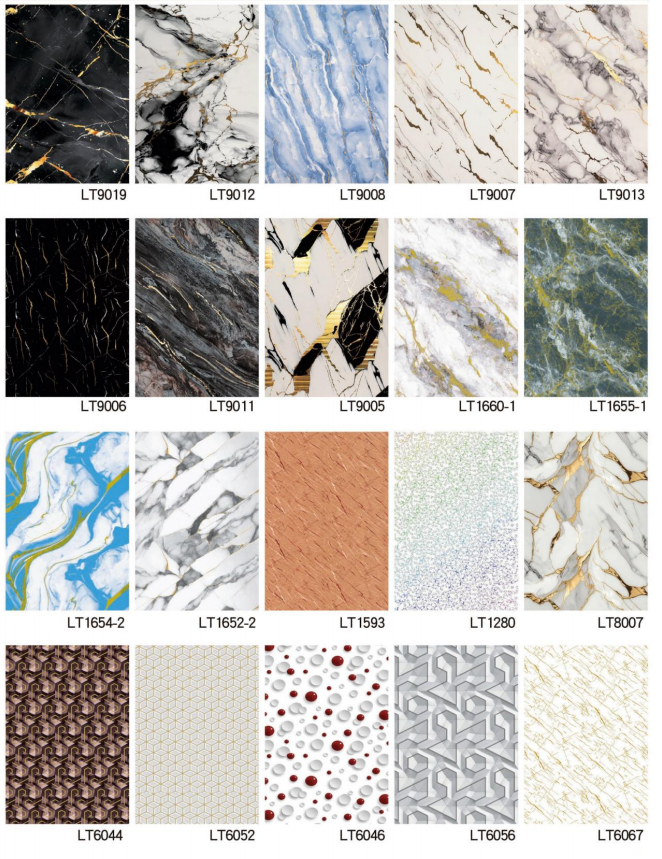

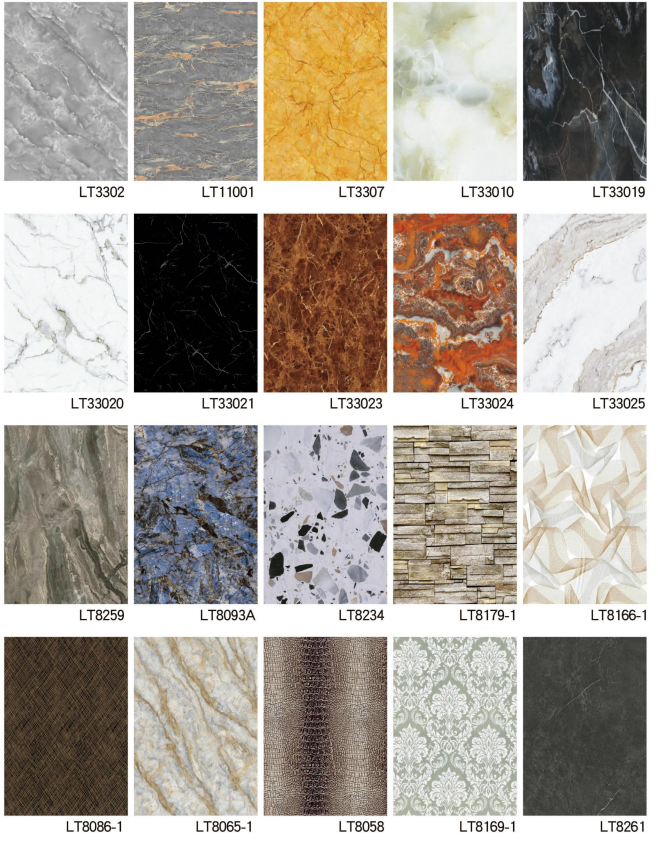

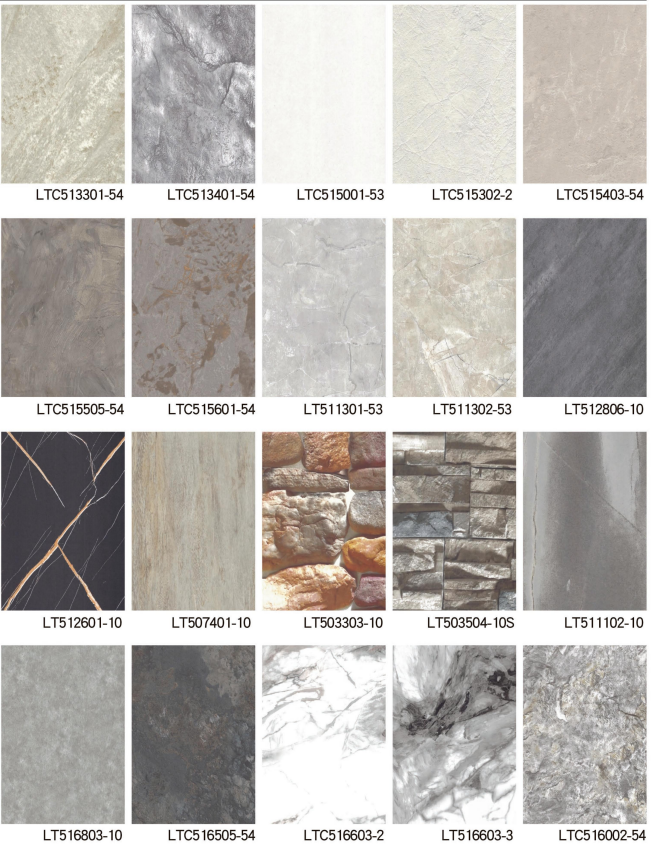

| Colors | Wide range of marble patterns including white, black, beige, gray, and custom patterns/colors on request |

| Standard Size | Length: 2440mm; Width: 1220mm; Thickness: 3mm, 4mm, 5mm (custom sizes available) |

| Surface Gloss | High-gloss, semi-gloss, or matte finishes available |

| Density | 1.6 - 1.8 g/cm |

| Fire Resistance | Fire-retardant properties (Grade B1) |

| Water Resistance | 100% waterproof and moisture-resistant, suitable for wet areas such as bathrooms and kitchens |

| Scratch Resistance | High scratch resistance due to advanced UV coating |

| UV Resistance | Excellent UV resistance, ensuring long-lasting color and gloss retention |

| Installation Method | Easy installation using adhesive or mechanical fixing |

| Weight | Lightweight and easy to handle, approximately 2-3 kg/m |

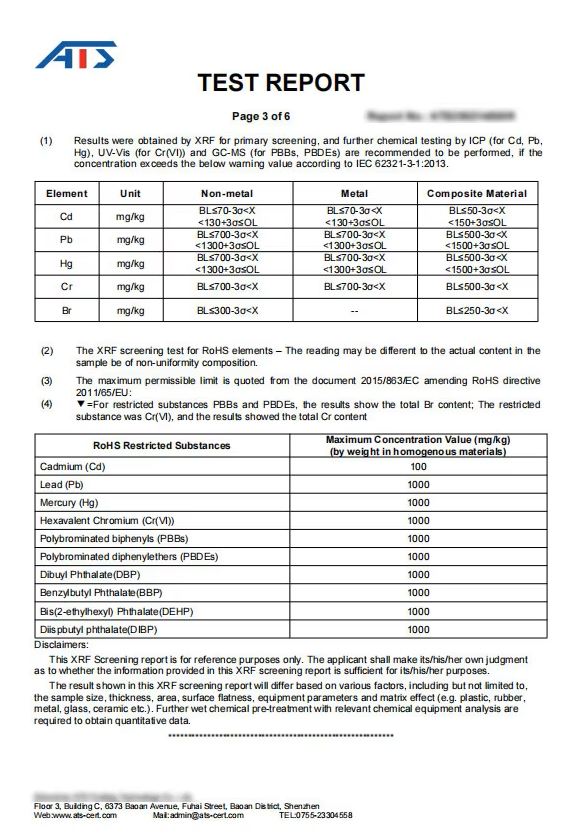

| Eco-friendliness | Non-toxic, lead-free, and environmentally friendly; recyclable materials |

| Maintenance | Low maintenance, easy to clean with a damp cloth, resistant to stains and discoloration |

| Durability | Long-lasting, withstanding daily wear and tear while maintaining its appearance |

| Service Life | Estimated to last 10-20 years with proper care and installation |

In the dynamic world of modern interior design and architecture, innovation constantly redefines the materials at our disposal. Among these, UV Marble Sheets have emerged as a popular and intriguing option. This engineered product, which involves printing a high-resolution marble pattern onto a composite base and sealing it with a layer of ultraviolet-cured resin, promises the luxury of stone without some of its traditional drawbacks. However, like any material, it presents a unique set of advantages and limitations.

A Symphony of Technology and Aesthetics

Unparalleled Aesthetic Versatility and Consistency

The most significant advantage of UV marble sheets is their visual appeal. Advanced digital printing technology can replicate the veining and color of virtually any natural marble, from the classic Statuario to rare and exotic varieties. This allows for a consistent and uniform appearance across large surfaces, eliminating the worry of mismatched slabs or undesirable natural clustering of patterns, which is common with natural stone.

Exceptional Durability and Practicality

The UV coating is the hero of this story. This hardened layer is highly resistant to scratches, stains, and moisture. Unlike porous natural marble, which can be easily stained by wine or lemon juice, a UV marble sheet can be wiped clean with a damp cloth. This makes it an excellent choice for kitchens, bathrooms, and high-traffic commercial areas where maintenance and hygiene are priorities.

Lightweight and Easy Installation

Composed of a thin composite core (often a blend of minerals and resins), these sheets are remarkably lightweight compared to slabs of natural stone. This drastically reduces the structural load on buildings and simplifies the installation process. They can often be installed directly over existing, flat surfaces using specialized adhesives, saving significant time and labor costs.

Cost-Effectiveness

For those desiring the opulent look of marble, UV sheets offer a fraction of the cost. The price of quarried, transported, and finished natural marble is prohibitively high for many projects. UV marble provides a democratizing effect, making a high-end aesthetic accessible for a broader range of residential and commercial budgets.

Eco-Friendly Credentials

As a manufactured product, it utilizes fewer natural stone resources. Furthermore, its production process can be designed to be more resource-efficient than quarrying massive stone blocks. For environmentally conscious consumers, this presents a more sustainable alternative to depleting natural marble reserves.

The surface finish is outstanding. Thanks to advanced techniques, it mimics natural marble's smooth, lustrous texture, is highly resistant to scratches and stains, and stays intact in busy kitchens or high-traffic commercial areas.

Yes, it's suitable. It has excellent weather resistance. The UV coating protects from sun damage, fading, cracking, and it can withstand rain, snow, and temperature fluctuations, applicable to building facades, balconies, and outdoor furniture.

UV Marble Sheet is more cost-effective. Real marble extraction, quarrying, and transportation are expensive, driving up cost. In contrast, it's manufactured economically, offers a similar look at a lower price, popular for budget marble-like effect seekers.