How Friendly HDPE Material is!

High-density polyethylene (HDPE) is a thermoplastic made from the polymerization of ethylene monomer. It has high density, high strength, chemical resistance, excellent electrical insulation properties and good heat resistance.

High-density polyethylene has high hardness and stiffness, and has good impact resistance and wear resistance, so it is widely used in various fields, such as packaging, pipes, containers, plastic bags, trash cans, etc. It is also an environmentally friendly plastic that can be recycled and helps reduce environmental pollution.

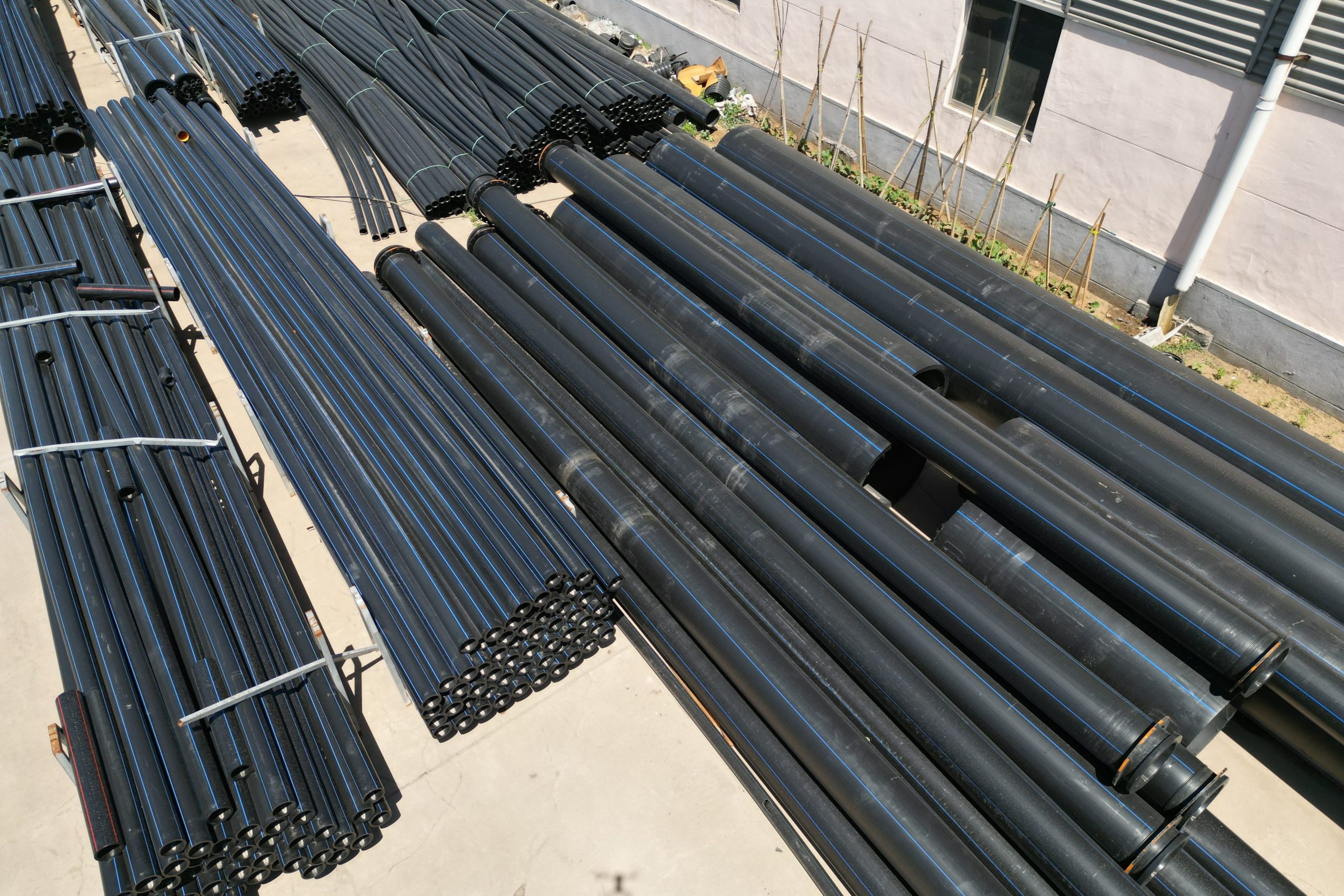

HDPE Pipes are Versatile

The market for HDPE pipes is currently booming and their versatility makes them the first choice across various industries and sectors.

- Water supply systems

HDPE pipes are ideal for conveying and distributing drinking water due to their excellent corrosion and chemical resistance and ability to withstand high pressure and temperature changes. - Agricultural irrigation systems

HDPE pipes are wear-resistant and can withstand high water pressure. Adapt to different irrigation needs. Its flexibility and ease of installation also make laying pipes in farmland more convenient. - Industrial piping system

HDPE pipes can withstand high-temperature operations, have good chemical stability, and adapt to the needs of various industrial environments. It can be used to transport industrial water to meet the needs of industrial production.

Choose HDPE Material instead of Metal Material

Compared with traditional metal materials, HDPE has significant advantages as a pipe material.

- Corrosion resistance

HDPE pipes have excellent corrosion resistance and can resist the erosion of chemicals and corrosive media. In contrast, metal pipes (such as iron pipes, copper pipes) are susceptible to corrosion, leading to pipe aging, leakage, and damage. - Lightweight and easy to install

HDPE pipe is relatively lightweight, making it easy to transport and install. In comparison, metal pipes are heavier and require more manpower and equipment to handle and install. The flexibility of HDPE pipe also makes the installation process easier and faster. - long lifespan and low maintenance costs

HDPE pipes have a long service life, generally up to 50 years or more. They won't rust or corrode. In contrast, metal pipelines require regular anti-corrosion treatment and maintenance, which increases maintenance costs and workload.

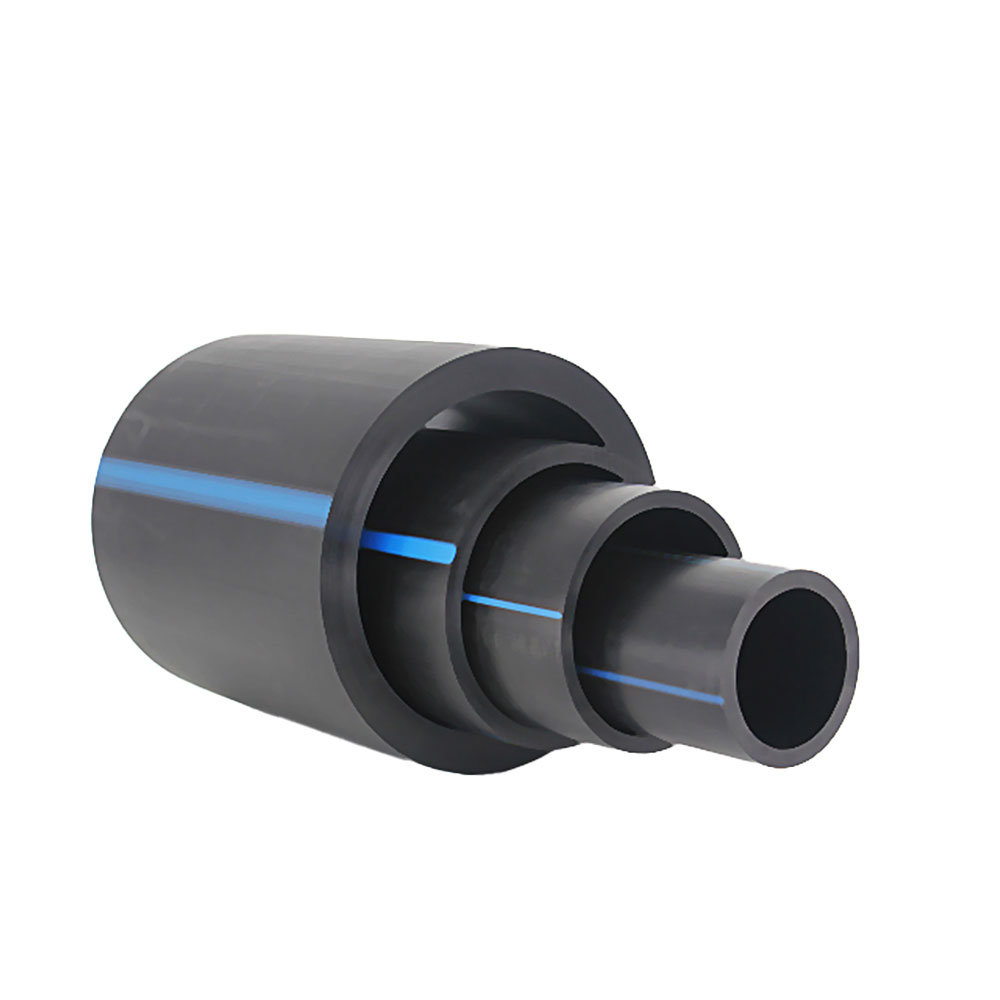

Wide Range of Sizes, Versatile Applications

HDPE pipe dimensions typically involve parameters such as outer diameter (OD), wall thickness (WT), and nominal pressure. These dimensions can be customized according to specific application requirements. Common HDPE pipe sizes include, but are not limited to, the following:

- Small Diameter HDPE Pipes

These pipes are commonly used for low-pressure applications such as agricultural irrigation and domestic water supply. Their outer diameter generally ranges from 20mm to 110mm. - Medium Diameter HDPE Pipes

These pipes are typically used for applications with medium pressure and flow rates, such as water supply, drainage, and industrial water usage. Their outer diameter generally ranges from 110mm to 630mm. - Large Diameter HDPE Pipes

These pipes are usually employed in high-pressure and high-flow applications, such as municipal engineering and oil transportation pipelines. Their outer diameter can exceed 630mm.

In summary, HDPE pipe dimensions offer a wide range of sizes to accommodate various applications. Depending on specific needs and engineering requirements, selecting the appropriate HDPE pipe size ensures the reliability, performance, and durability of the pipe system.

You are welcome to : phone call, Message, Wechat, Email& Seaching us, etc.