In the world of plumbing and construction, materials that offer a combination of durability, cost-effectiveness, and versatility are essential. Among these, PVC pipes have emerged as a leading choice due to their superior properties and wide range of applications. But what exactly makes PVC for pipes such a valuable material, and how does it differ from other piping options?

What is PVC?

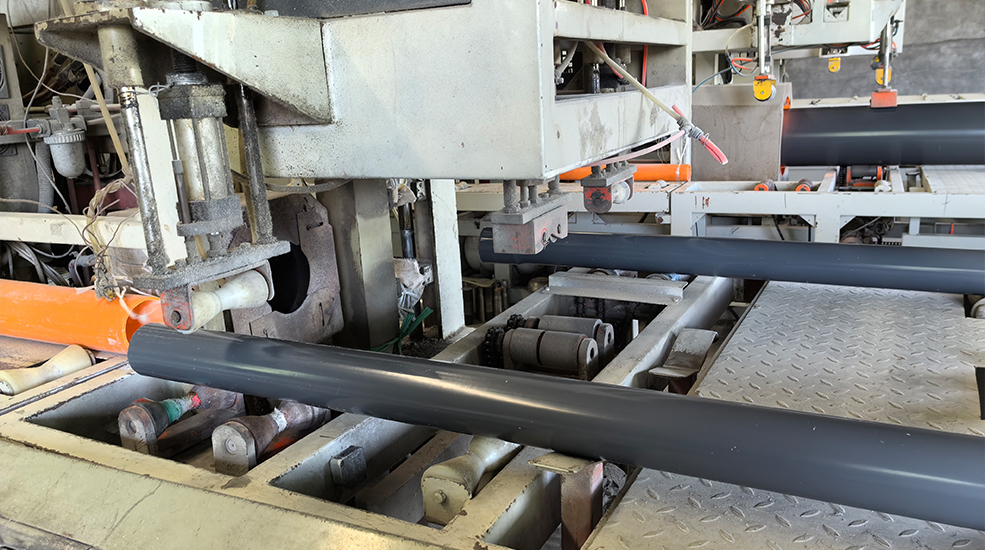

PVC, or polyvinyl chloride, is a type of plastic that has become one of the most widely used materials in construction, particularly for piping. PVC plastic piping is made from a combination of vinyl and plastic, which provides an ideal balance of flexibility, strength, and resistance to corrosion. These characteristics make plastic PVC pipe highly suitable for both residential and industrial applications, including water supply, drainage, and sewage systems.

PVC pipes were first introduced in the mid-20th century as a replacement for metal pipes, which were prone to rust, corrosion, and degradation over time. Since then, the use of PVC pipes has skyrocketed, especially in the plumbing industry. Unlike traditional metal pipes, PVC does not corrode when exposed to water or other chemicals, making it an excellent choice for both hot and cold water systems.

Moreover, PVC pipes are lightweight, which simplifies installation and reduces transportation costs. This has made them a preferred material for contractors and plumbers worldwide. The development of different types of PVC pipes and PVC pipe fittings has also expanded their range of applications, from residential plumbing to large-scale industrial systems.

PVC Pipe Sizes and Dimensions

One of the key advantages of using PVC plastic pipe is the wide variety of sizes and dimensions available. PVC pipes come in different diameters and thicknesses, allowing them to be used for various purposes, from carrying drinking water to venting exhaust gases. The PVC plastic pipe dimensions are standardized, making it easier to choose the right size for any specific application.

Here is a brief overview of common PVC pipe sizes:

- Schedule 40 PVC Pipes

These are the most common type of PVC pipes used in residential and commercial plumbing. They have a standard wall thickness and are used for both pressurized and non-pressurized applications. Sizes range from ½ inch to 24 inches in diameter. - Schedule 80 PVC Pipes

These pipes have thicker walls compared to Schedule 40 pipes, making them suitable for high-pressure applications. They are commonly used in industrial settings and come in sizes ranging from ½ inch to 24 inches in diameter. - Thin-Walled PVC Pipes

These are lightweight pipes often used for low-pressure applications like drainage or irrigation. They are available in sizes from 1 inch to 12 inches in diameter.

The diversity in PVC pipe sizes ensures that there is a PVC pipe suitable for every plumbing need, whether it is a small residential installation or a large-scale industrial project.

Applications of PVC Pipes

Water Supply Systems: One of the most common uses of PVC pipes is in water supply systems. PVC for pipes in water systems offers durability and resistance to both temperature changes and chemical reactions. These pipes are used in delivering potable water in homes, businesses, and industrial facilities.

- Sewage and Drainage Systems

PVC pipes are frequently used in sewage and drainage systems due to their resistance to corrosion and chemical degradation. They can handle large volumes of water and waste without the risk of bursting or leaking, which is critical in maintaining a healthy and safe environment. - Irrigation Systems

In agriculture and landscaping, PVC pipes are popular for irrigation systems. Their lightweight nature and flexibility make them easy to install in various terrains, and their durability ensures they can withstand harsh environmental conditions. - Electrical Conduits

PVC pipes are also used as electrical conduits to protect wires and cables from moisture, chemicals, and mechanical damage. This application is crucial in both residential and industrial settings, where protecting electrical components is of utmost importance. - HVAC Systems

PVC pipes are commonly used in heating, ventilation, and air conditioning (HVAC) systems. They help to vent exhaust gases safely outside buildings and are resistant to the heat and pressure typically found in such systems.

PVC Pipe Fittings: Essential Components for Versatility

PVC pipe fittings are essential components in any PVC piping system. They include a variety of connectors, adapters, elbows, tees, couplings, and valves that allow for the customization and expansion of piping networks. These fittings are designed to provide a leak-proof connection and are available in various shapes and sizes to accommodate different piping layouts and applications.

Common types of fittings for PVC pipes include:

- Couplings

Used to connect two straight pipes of the same diameter. - Elbows

Designed to change the direction of a pipe, typically at 90 or 45 degrees. - Tees

Allow for branching off a main pipeline, essential in complex plumbing systems. - Adapters

Used to connect PVC pipes to other materials or different types of pipes. - Caps and Plugs

Used to close the ends of a pipe, providing a seal against leaks.

These fittings make PVC pipes highly adaptable and versatile, capable of being tailored to the specific needs of any plumbing or construction project.

Advantages of Using PVC Pipes

- Durability

PVC is resistant to corrosion, chemicals, and abrasion, making it ideal for long-term use in different environments. - Cost-Effectiveness

PVC pipes are relatively inexpensive to manufacture, transport, and install, which reduces overall project costs. - Lightweight

Their lightweight nature makes PVC pipes easy to handle and install, saving on labor and time. - Versatility

With a wide range of sizes, thicknesses, and fittings, PVC pipes can be customized for almost any 、plumbing or construction need. - Low Maintenance

PVC pipes require minimal maintenance, reducing long-term costs and ensuring a reliable piping system.

Challenges and Environmental Considerations

While PVC pipes offer numerous benefits, there are also some challenges and environmental considerations. The production of PVC involves the use of chemicals such as chlorine and phthalates, which have raised environmental concerns. Additionally, improper disposal of PVC can contribute to plastic pollution.

However, advancements in recycling technologies have made it possible to recycle PVC materials more effectively, reducing their environmental impact. Furthermore, PVC pipes have a long lifespan, reducing the need for frequent replacements and minimizing waste.

Conclusion: The Future of PVC Pipes

As the demand for reliable, durable, and cost-effective piping solutions continues to grow, PVC pipes are set to remain a cornerstone of the plumbing and construction industries. With their wide range of applications, from water supply to irrigation and electrical conduits, PVC pipes offer unmatched versatility.

Innovations in material science and recycling processes will likely enhance the sustainability of PVC plastic piping, ensuring that it remains an integral part of modern infrastructure for years to come. Whether in residential plumbing, industrial systems, or agricultural irrigation, PVC pipes have proven to be a material that stands the test of time.

You are welcome to : phone call, Message, Wechat, Email& Seaching us, etc.